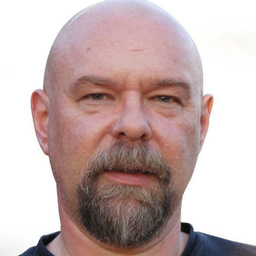

Tom Kerpert

Angestellt, Creative Designer, HL Display - the better shopping experience

Wien, Österreich

Werdegang

Berufserfahrung von Tom Kerpert

Bis heute 6 Jahre und 6 Monate, seit Jan. 2018

Creative Designer

HL Display - the better shopping experience• Industrial and Product Design services to the plastic and related industries • Clients – Astrapak group, Consol, Nampak, Maxistar, BI Polycontainers, Winplas, Zodiac, Brentt Instruments, Novocare, Blowpet, Elvin, Nandos etc. • Consulting on production and quality problems to clients • General engineering design • Writing of general and quality related procedure manuals • Assistance in ISO 9001 implementation to clients • 3D printing for client presentation

1999 - 2004

Quality Assurance Manager, Product Development Manager

Cinqplast – Plastop

• Writing and implementing ISO 9001 procedures throughout the company • Setting of quality standards and specification • Control of the quality assurance and quality control departments • Customer quality liaison • Trouble shooting on production, quality and client issues • Design and development of new rigid plastic packaging • Consulting on customer production lines • Project management and implementation of new production technologies

1997 - 1999

Operations Director

Sodaclub SA

• Setting up and running the local Sodaclub operation as green fields project • Setting up new production facilities including • Factory and warehousing design • Mixing operation and filling line for cool drink syrups • CO2 cylinder filling line • Assembly and packaging line for home carbonation systems • Design and implementation of food oriented quality control systems and procedures • Purchase of plant and raw material • Operational planning and control

1993 - 1997

Technical Manager, Operations Manager

SA Moulded Plastics

• Control of a plastic injection moulding operation specialised in technical injection moulded products ( BMW, Mercedes, Siemens and general telecoms products) with 63 moulding machines and 450 employees • Management control of the production, maintenance and engineering departments • Assisting Marketing and Sales in Product Development • Full budget responsibilities for these departments • Writing and implementation of ISO 9001 procedures

1989 - 1993

Divisional Development Director

Kohler Plastics

• Product and technical development services for the rigid plastics division • Research and development of new production methods • Strategic technology planning for the division • Customer liaison on new packaging projects • Consulting on customer filling and packing operations • Extensive international travel on research projects • Liaison with Corporate and multinational clients on packaging strategies and rationalisation projects

1981 - 1989

Product Development Manager, QA Manager, Technical Manager, Technical Director

Xactics, Kohler – Xactics, Kohler Plastics

• Design and development of new rigid plastic packaging • Research and development of new production methods • Purchase of new plant and equipment • Setting of quality standards and specifications • Introduction of new manufacturing technologies • Development of production procedures • Consulting on clients filling lines

1977 - 1981

Packaging and O&M Engineer

Unilever Frozen Food Division – Austria

• Packaging design and development in various materials for the ready meal division • Production line layout • Manufacturing costing • Setting of production standards • Rationalisation projects • Introduction of new filling and packing methodologies • General industrial engineering duties • Rationalisation projects

Ausbildung von Tom Kerpert

1977 - 1979

Industrial Engineering

Wifi Wien

1970 - 1976

Kunststofftechnik

TGM Kunststofftechnik Pl76b

Sprachen

Englisch

Fließend

Deutsch

Muttersprache